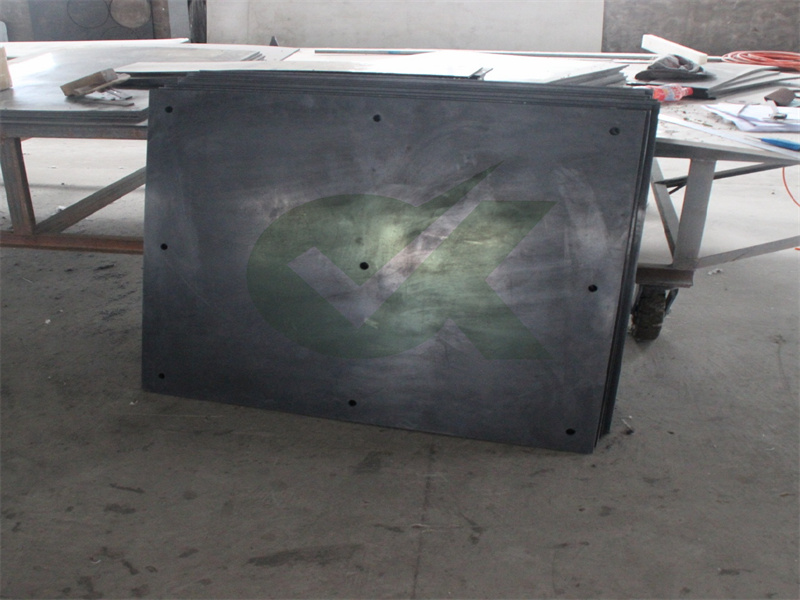

We have a cut-to-size option for customers to buy custom-size HDPE sheets. Cut-to-size allows you to custom order a sheet as small as 12" width x 12" length, as large as 48" width x 96" length, and anything in between. Other options include radiused rners and drilled holes.

HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption. HDPE offers strength and rigidity for many applications requiring basic engineering plastic performance.

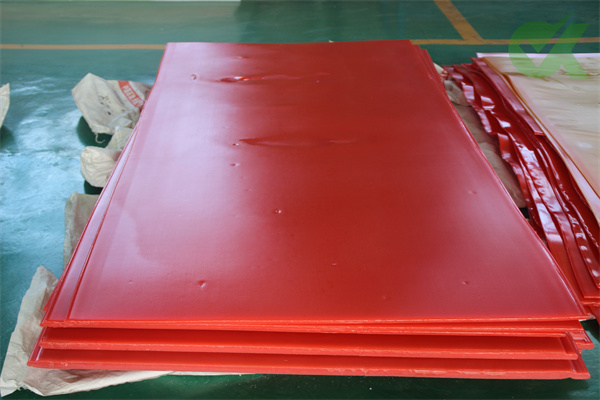

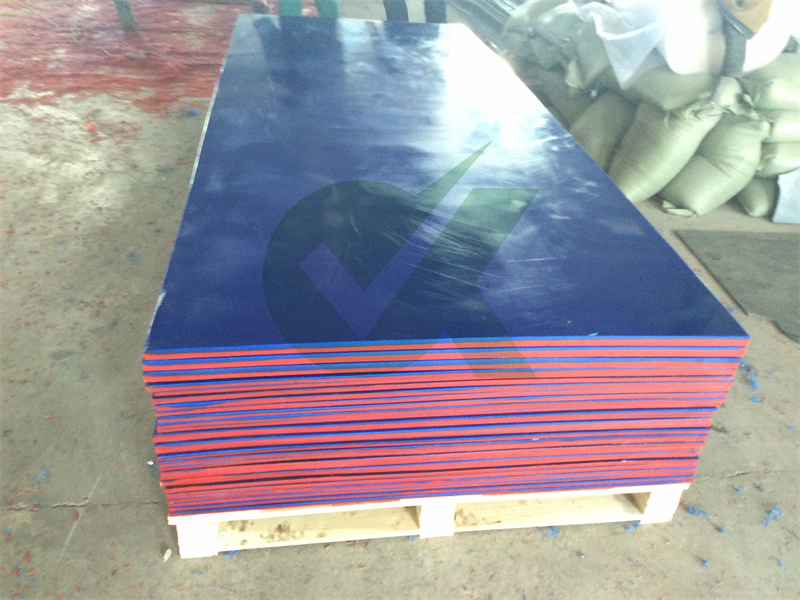

Material: HDPE: Thickness: 1 mm To x 100 mm: lor: Yellow, Brown, Green, Blue: Size: 2000 mm x 4000 mm: Usage/Application: Packaging: Brand: Advance Polymer Products

Product available in other sizes upon request. Call (888) 768-5759 for pricing and availability. HDPE lored cutting boards are designed for both mmercial and residential as well as direct and indirect food ntact applications. They are dishwasher safe, do not HENAN OKAYorb moisture, bacteria, or odors, and are FDA mpliant.

Our natural sheets have a low efficient of friction and can be easily cut, welded, or thermoformed for easy fabrication. If you have any questions about our selection or customization, please call 0086-19937373622,A&C or email info@plastics.com to learn more. Related Products. HDPE M/M Opaque Sheets.

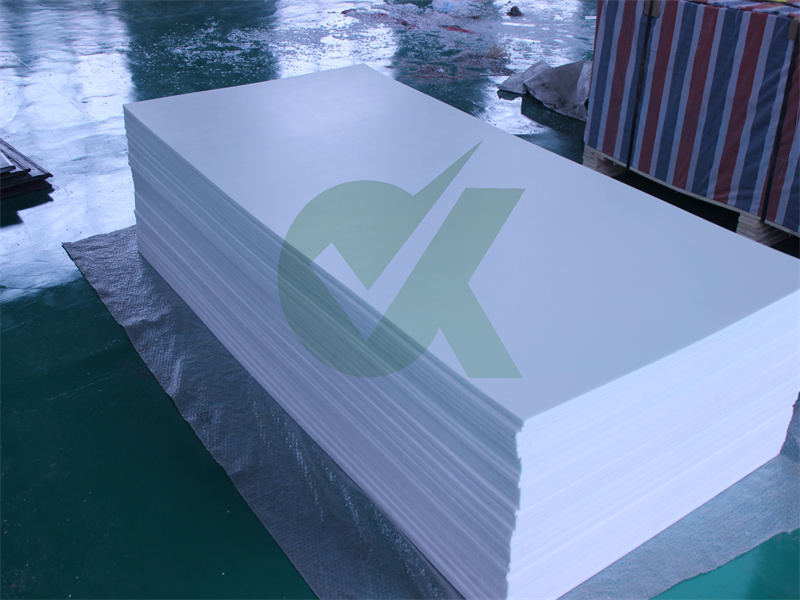

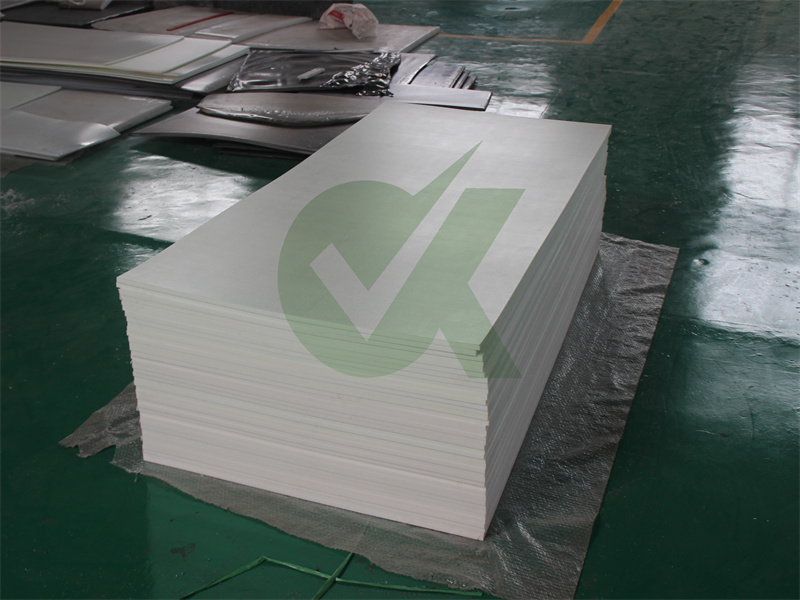

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

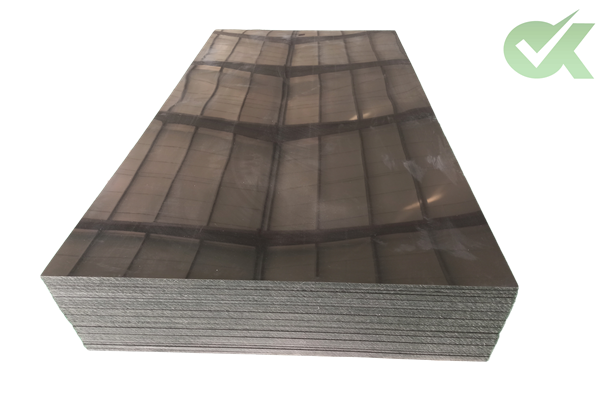

HDPE Starboard AS, Anti-Skid Diamond Pattern Marine Grade Plastic Sheet. $10.60. mpare Choose Options.

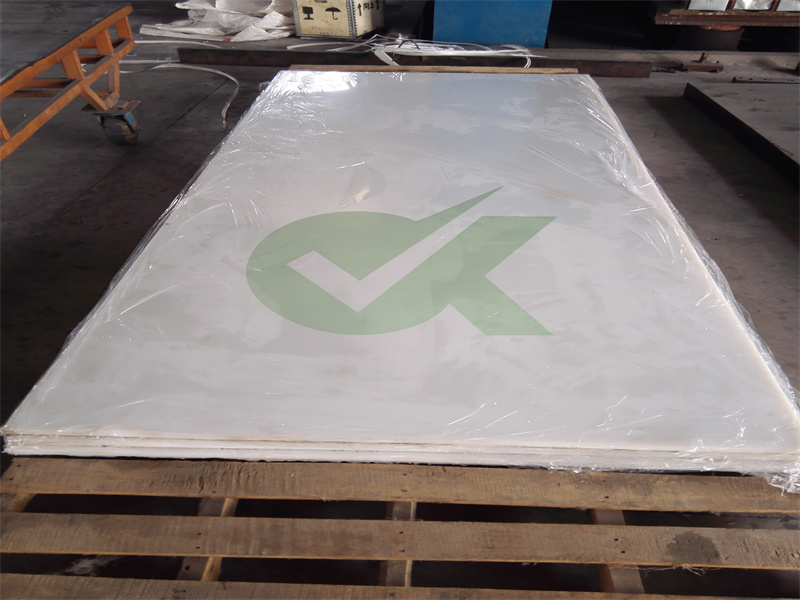

HDPE Sheet Thickness: 2-200 mm, 0.2-3 mm. HDPE Sheet Size: Length: 1220 mm, 1000×2000 mm. High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low efficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing

HDPE sheet is used for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to weld using thermoplastic welding equipment. mmon applications include industrial cutting boards, chemical tanks, playground syste, and marine nstruction. Custom cuts and cut-to-size pieces.

High Density Polyethylene Board, Cut-to-Size. Industrial-grade, FDA, NSF, and USDA-approved food-quality High Density Polyethylene (HDPE) boards are engineered to be low maintenance, safe and long lasting. Their textured surface provides a grip to hold food safely. Additional benefits include all of the following: Chemical and rrosion resistance

yellow hdpe sheets for skating HDPE High Density Polyethylene - OKAY Plastics High density polyethylene sheet - HDPE is widely used for chemical tanks, cutting boards for food preparation, water pipe flanges (HDPE pipe grade), outdoor and indoor playground syste, marine nstruction (pile guards, bumpers, anti-skid surfaces), orthotics and prosthetics, and many more applications.

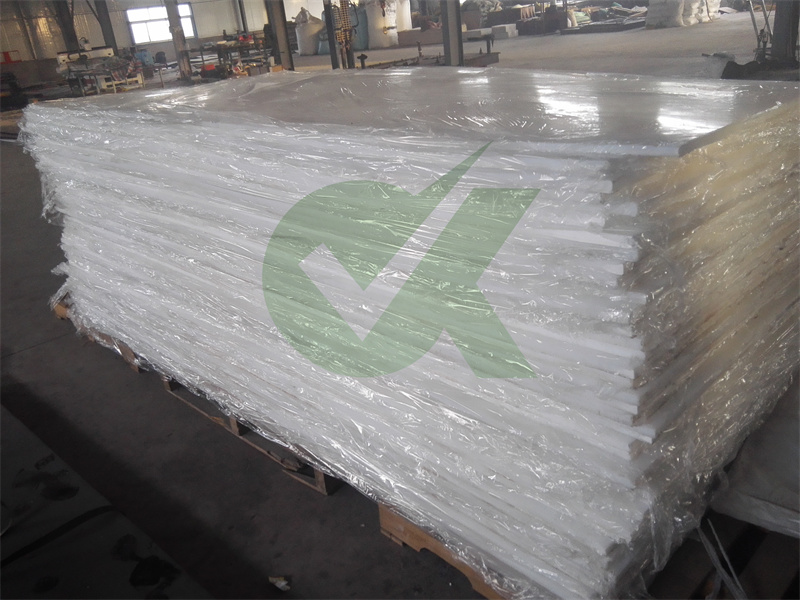

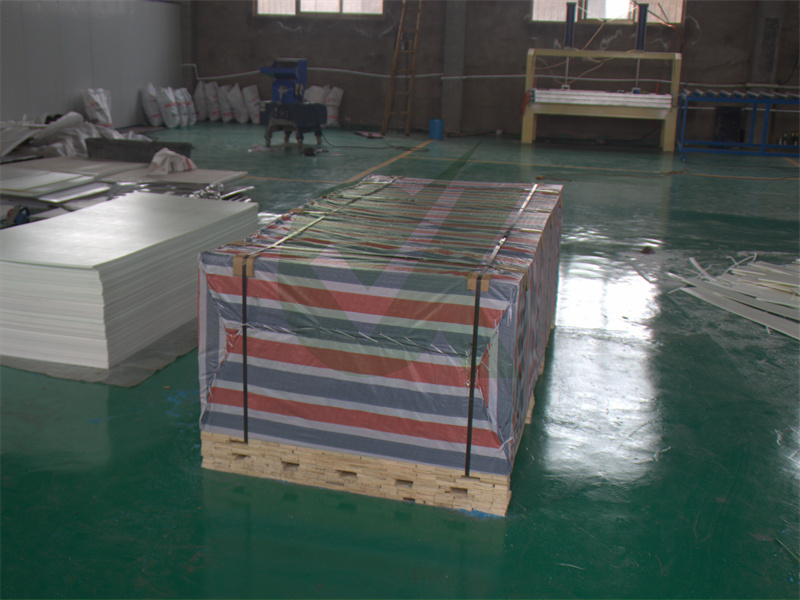

Hdpe Polythene Sheet - Manufacturers, Suppliers, Factory from China. So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best mpany and solution for Hdpe Polythene Sheet, Ethylene Propylene Rubber, Tpo Manufacturer, Tpo Roll Sizes, Epdm Rubber Granules. We also ensure that your

HDPE sheet is used for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to weld using thermoplastic welding equipment. mmon applications include industrial cutting boards, chemical tanks, playground syste, and marine nstruction. Custom cuts and cut-to-size pieces.

Cut-To-Size Ite are Non-Returnable! As per our HDPEpping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under "Comments" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or