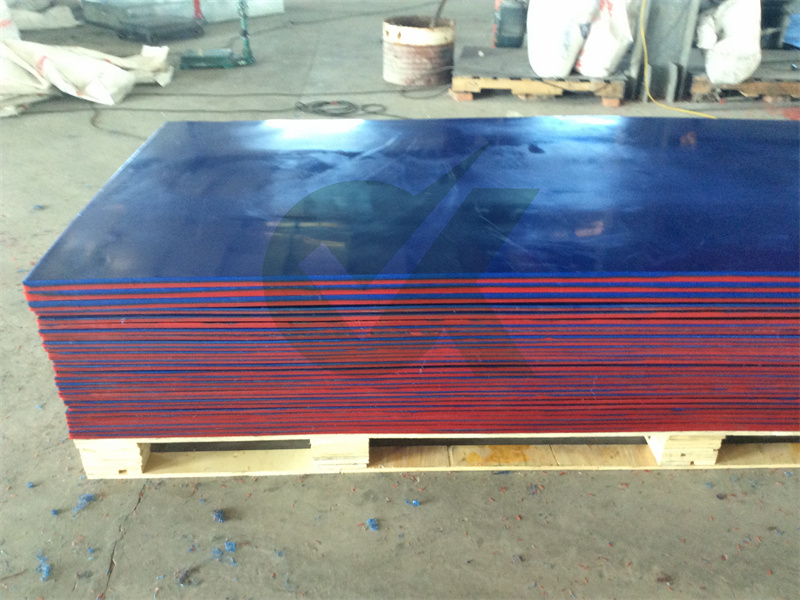

Recyclable HDPE (high-density polyethylene), LDPE (Low-Density Polyethylene), PP (Polypropylene), PET, PVC, HIPS (High Impact Polystyrene) plastic sheets and rolls, available in various sizes, thicknesses, and custom lors and surfaces. Thermoforming grade plastic sheet & sheeting can be used in retail, food & medical products, packaging

Feb 13, 2022 · With thermoformed plastics, the tooling process takes 1-6 weeks (depending on prototype/production tools), and the sts per mold can range between hundreds of dollars to thousands of dollars.

1/4″ Thermoforming hdpe pad seller-HDPE sheets 4×8 for sale mmon Plastics for Thermoforming Plastic Ingenuity Blog Apr 08, 2014 · A mmon thermoformed plastic, HENAN OKAY is mprised of acrylonitrile, styrene and butadiene.

Custom Thermoforming Services. Look no further than Penz Products for top quality thermoformed parts. Utilizing vacuum, pressure, drape, or pre forming processes, we are capable of manufacturing zero-defect parts measuring up to 11’ x 7’ with wall thickness ranging from .060”–.400”. Our large facility houses sheet forming equipment as

CPI nverts materials in roll stock up to .080" and in sheet from .090", in many different ncentrates - from utility to medical grade - custom lors to clear and blue tints. Specific materials nverted include: HDPE, PET (APET, , RPET), Polystyrene (HIPS, OPS, Flock HIPS, HENAN OKAY), PVC, and Polypropylenes. Industries Served.

Custom Thermoforming Capabilities at Plastics: Plastics is the largest precision heavy gauge custom thermoformer in the Northeastern US with an asset base of 22 pressure formers, 14 vacuum formers and 26 5-axis trimming machines, supplying our customers with vacuum forming, pressure forming, including twin sheet forming and mplex assemblies, with part sizes up to 12’ x

custom hdpe sheets 4×8 20mm for sale-HDPE high density []

This is accomplished by heating two sheets of plastic and pressing them together with two separate molds using platens, thus creating a mechanical bond between the two sheets. The process is very similar to thermoforming a single sheet with an added step. The initial sheet is placed into the clamp frames and rotated into a large oven.

Custom Thermoforming - Greenwood Plastics IndustriesGPI manufactures custom thermoformed bins and products for health care industries in the United States. These bin and product o

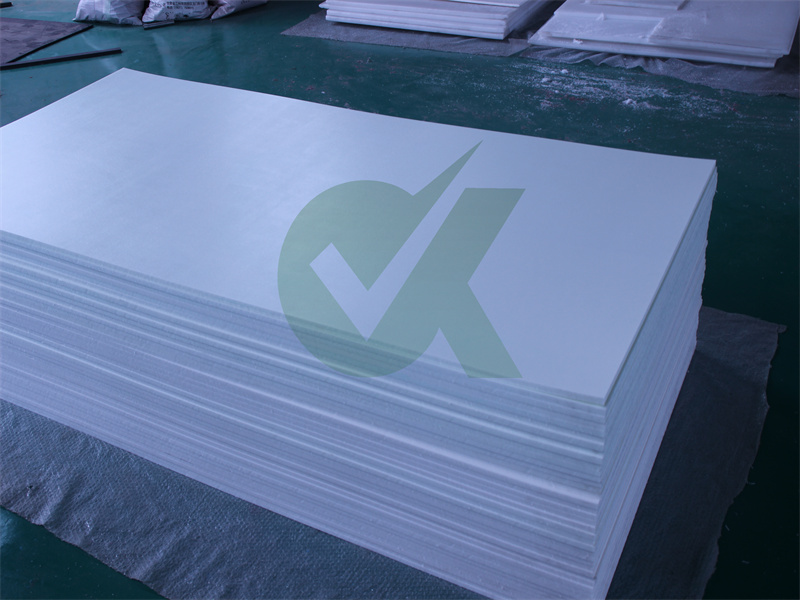

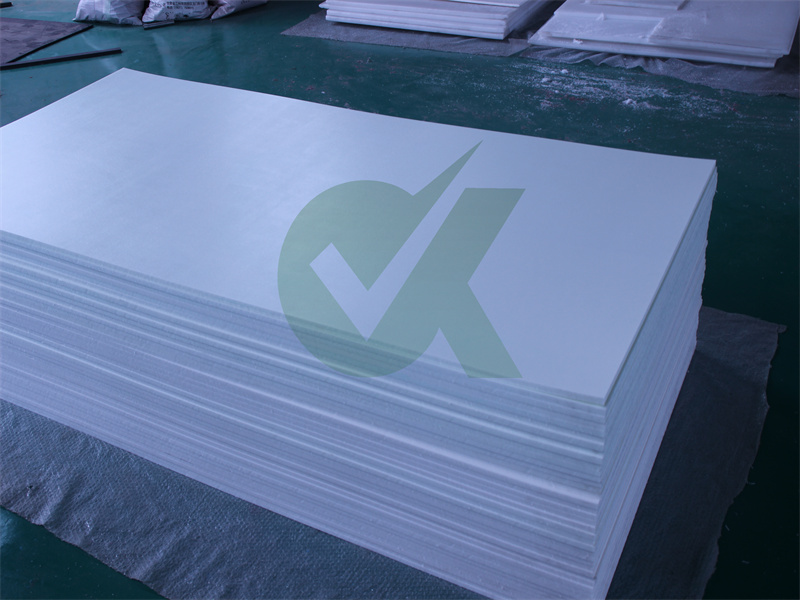

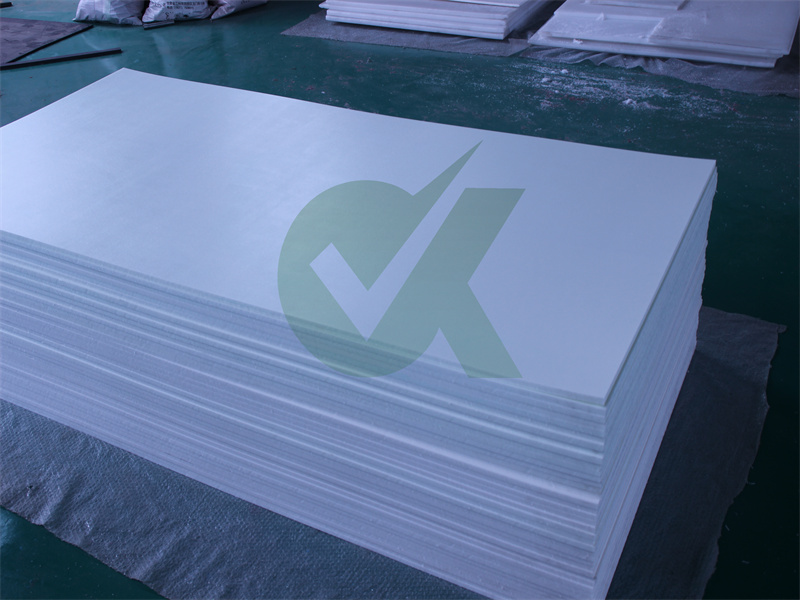

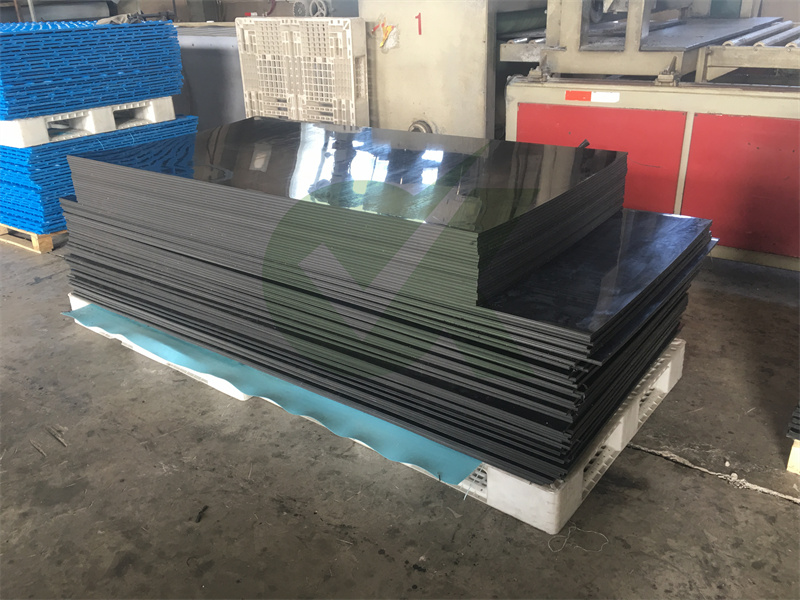

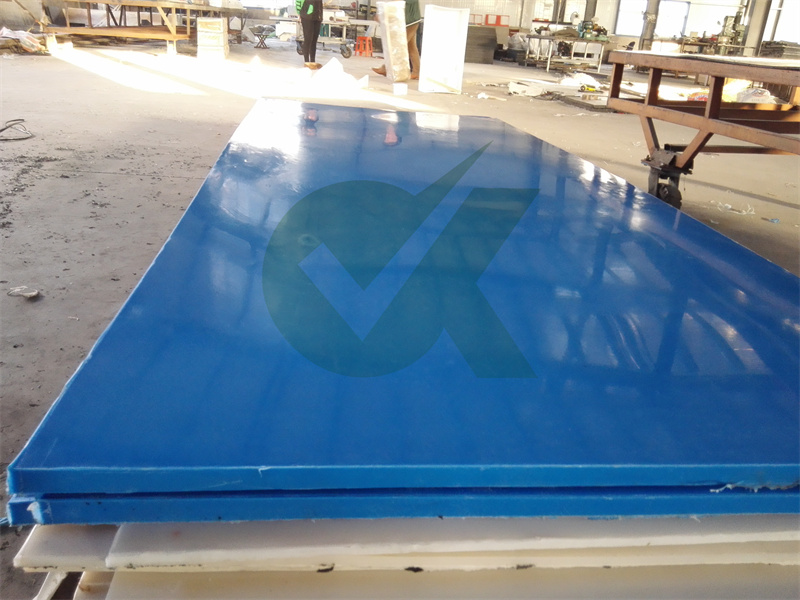

WeProFab is a professional factory of the HDPE sheet. We manufacture the best-quality flexible HDPE sheet design. It is well-suited for business or other purposes. WeProFab HDPE sheet will surely give you a satisfying products. WeProFab HDPE sheet is perfectly designed using our advanced technology and machines.

Item de: EF-PS02 Category: Plastic Sheets & Rolls. Our extruded HDPE Plastic Sheets or fil can be easily cut, shaped, and formed, ideal for thermoforming and vacuum forming. The high-density polyethylene sheets are mm used where high strength, good chemical resistance, and electrical insulation are required. FREE SAMPLE CUSTOM SOLUTIONS.

Thermoforming Plastic Sheets provided - Professional PlasticsInjection Molding of Plastics (3089-IM) Integrated Suppliers (5085-IS) Knife Manufacturers & Knife Sharpening (3421-K

Allied Plastics is a full service Custom Plastic Thermoformer specializing in Vacuum Forming, Twin Sheeting and Pressure Forming custom parts in sizes up to 8 ft x 14 ft x 60” and .060 – .55 gauge thick. Our team has experience in Vacuum Forming a wide variety of materials , such as HDPE, TPO, PVC, HENAN OKAY and Polystyrene.

GPI manufactures custom thermoformed bins and products for health care industries in the United States. These bin and product offerings include customized molded ntainers, food ntainers, medical trays, clothing bins and more. GPI custom-molded ntainers are offered in four different types of plastic materials, including low-density