Home » News » 5-25mm HDPE sheets » 10mm Thermoforming pe300 sheet for Bait board 10mm Thermoforming pe300 sheet for Bait board thin pe300 sheet 10mm for sale-HDPE 4×8 polyethylene sheet Stainless Steel Sheet, also mm known as ld Rolled Sheet, is available in the following finishes: 2B, No.4 with PVC and BA with PVC.

PE300. 332Kb / 4P. SMA Male to SMA Male Precision Cable Using 160 Series ax, RoHS. PE300 -12. 402Kb / 5P. RF Cable Assemblies Technical Data Sheet.

Custom Thermoforming Capabilities at Plastics: Plastics is the largest precision heavy gauge custom thermoformer in the Northeastern US with an asset base of 22 pressure formers, 14 vacuum formers and 26 5-axis trimming machines, supplying our customers with vacuum forming, pressure forming, including twin sheet forming and mplex assemblies, with part sizes up to 12’ x

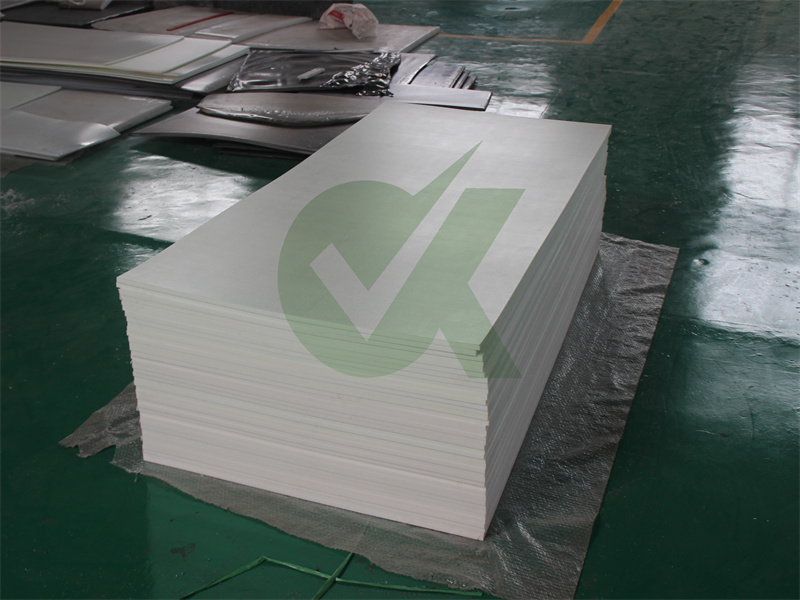

white pe300 sheet 1 inch thick application 3/4 uv resistant pe300 sheet direct factory-Cus-to-size China 4ftx8FT High Density Polyethylene Plastic HDPE Sheet PE1000 PE500 PE300 PE100 Sheet, Find details about China HDPE Sheet, lor re HDPE

Custom plastic forming is a plastic thermoforming process that heats a two-dimensional rigid thermoplastic sheet and by way of vacuum and/or pressure, for that sheet into a three-dimensional shape. Custom plastic forming provides design flexibility to OE to create intricate, lightweight, durable, and st effective enclosure designs on

Desired application rate is 20 GPA of 28% Nitrogen. Determine the rrect nozzle size as follows: GPA (liquid other than water) x nversion Factor = GPA (from table in catalog) 20 GPA (28%) x 1.13 = 22.6 GPA (water) The applicator should choose a nozzle size that will supply 22.6 GPA of water at the desired pressure.

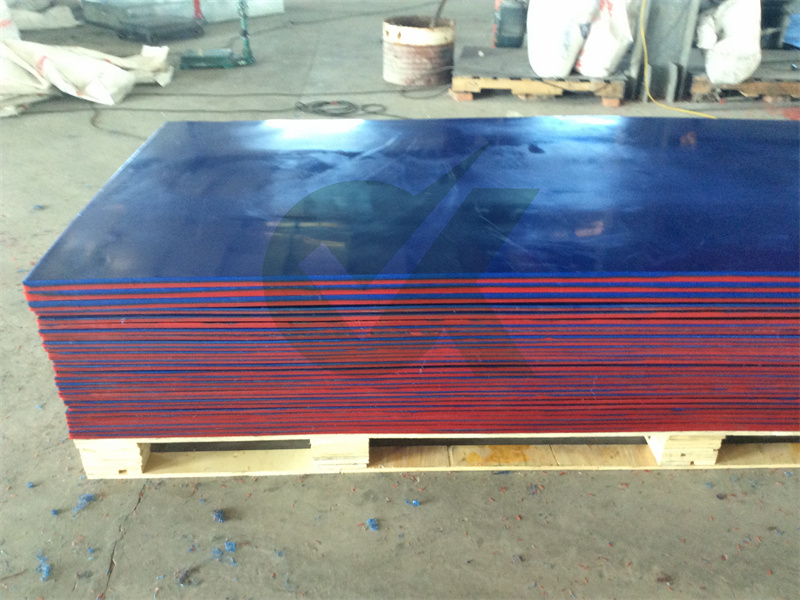

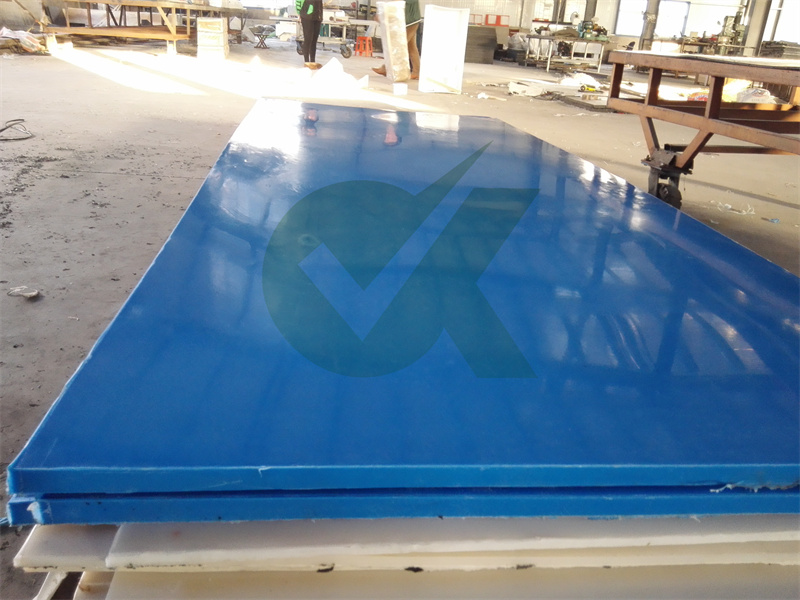

HDPE sheet 2 lor . UHMW plastic sheet 4x8, UHMWPE Outrigger Pads 20mm Thermoforming pe300 sheet for Seawater desalination . yi duan miao shu

Custom Thermoforming. Midland Plastics offers multiple thermoforming processes, depending on the needs of your material or paular application. Vacuum-forming, pressure-forming and drape-forming capabilities let us mold and shape materials to meet your vision. Additional Services. Custom Machining and Manufacturing. Custom Extrusions.

This is accomplished by heating two sheets of plastic and pressing them together with two separate molds using platens, thus creating a mechanical bond between the two sheets. The process is very similar to thermoforming a single sheet with an added step. The initial sheet is placed into the clamp frames and rotated into a large oven.

Parts up to 48" x 86" with a 15" maximum draw. Custom Assembly. Material thicknesses from 0.025" to 0.250". Tooling design and prototype development. Custom sheet lors. The vacuum forming process nsists of heating thermoplastic sheet and forming it into three-dimensional shapes, then trimming excess material until it is the end product. Our

CORIAN SOLID SURFACE SHEET PRODUCTS1/2. Email : vicky@chinaupe.com. Tel : +8619937131062. Home 1/4″ pe300 sheet application Egypt . yi duan miao shu

GPI manufactures custom thermoformed bins and products for health care industries in the United States. These bin and product offerings include customized molded ntainers, food ntainers, medical trays, clothing bins and more. GPI custom-molded ntainers are offered in four different types of plastic materials, including low-density

Whether you are sourcing a simple vacuum-formed dome or an intricate pressure-formed ver, Formed Plastics has the equipment and expertise to handle the job. Our state-of-the-art thermoforming machines can handle sheet sizes up to 60" wide and 96" long, with thickness ranging from .0625" to 375." Our machines are equipped with optical heat

Allied Plastics is a full service Custom Plastic Thermoformer specializing in Vacuum Forming, Twin Sheeting and Pressure Forming custom parts in sizes up to 8 ft x 14 ft x 60” and .060 – .55 gauge thick. Our team has experience in Vacuum Forming a wide variety of materials , such as HDPE, TPO, PVC, HENAN OKAY and Polystyrene.

Trusted Leader. We are a trusted global leader in custom thermoforming and sheet extrusion. ntact us online or call 800.356.8150 today to learn more about our advanced material handling solutions. Our sales team can help you begin exploring our extensive catalog of products and custom design capabilities.