Injection Molding of Plastics (3089-IM) Integrated Suppliers (5085-IS) Knife Manufacturers & Knife Sharpening (3421-KN) Laser Equipment & Precision Optics (3699-LE) Lighting Products (3648-LP) Machinery - Not Otherwise Classified (3569) Machine Tool Manufacturer (3541-MT) Machining - CNC Machine Shops (3599) Machining - Plastic Specialty (3599-PM)

Allied Plastics is a full service Custom Plastic Thermoformer specializing in Vacuum Forming, Twin Sheeting and Pressure Forming custom parts in sizes up to 8 ft x 14 ft x 60” and .060 – .55 gauge thick. Our team has experience in Vacuum Forming a wide variety of materials , such as HDPE, TPO, PVC, HENAN OKAY and Polystyrene.

Custom Hdpe Sheets Related Videos From okay Octavia .02.16 05:20:16 This manufacturers not respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully mpleted the procurement tasks.

Guideline. Global Thermoforming, Inc is a leader in the thermoforming plastics industry that provides thermoforming, vacuum forming, clahell, clahell packaging, thin gauge thermoforming, thick gauge thermoforming, and a variety of other services to the entire United States. We have local thermoforming facilities in Tempe, AZ and Nashville, TN.

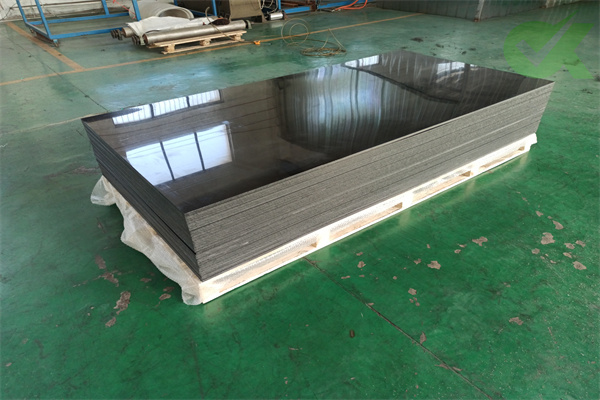

DK Plastics. DK Plastics was established in 1995 to help meet the growing needs for heavy gauge sheet plastic. We are a successful, family-owned rporation, with our manufacturing facilities headquartered in Archer, Iowa. Our Parent mpany, Dave De Kok, Inc. was established in 1963. In 1998, we extruded our first HDPE sheets in a new 6000

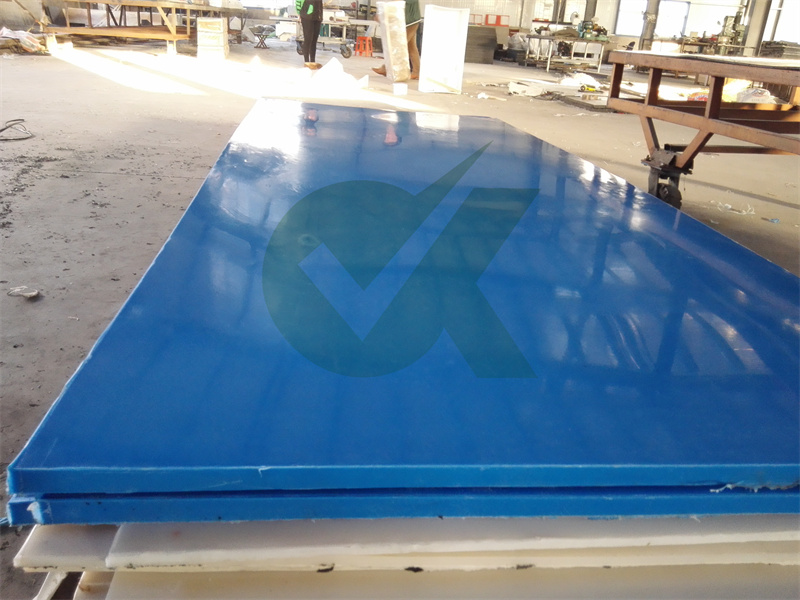

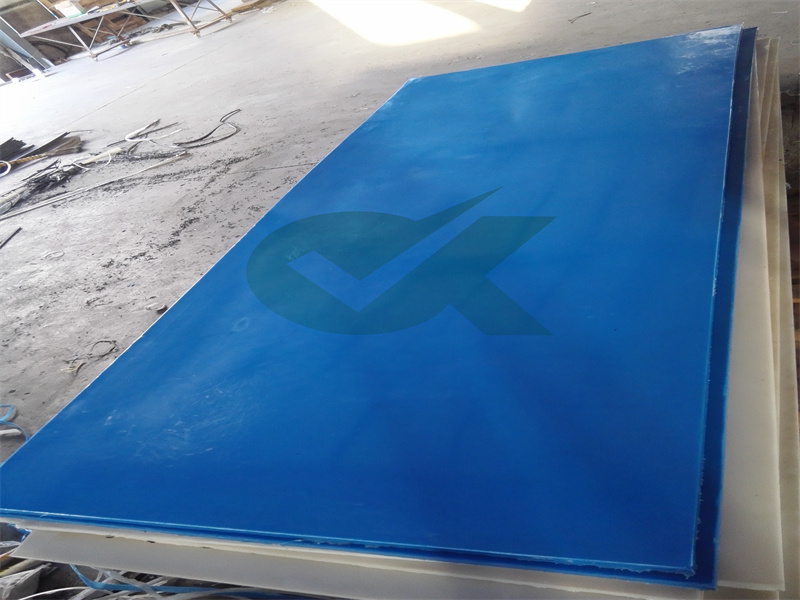

Our natural sheets have a low efficient of friction and can be easily cut, welded, or thermoformed for easy fabrication. If you have any questions about our selection or customization, please call 0086-19937373622,A&C or email info@plastics.com to learn more.

Whether you are sourcing a simple vacuum-formed dome or an intricate pressure-formed ver, Formed Plastics has the equipment and expertise to handle the job. Our state-of-the-art thermoforming machines can handle sheet sizes up to 60" wide and 96" long, with thickness ranging from .0625" to 375." Our machines are equipped with optical heat

The mplex design of this snowmobile fuel tank was manufactured using twin sheet thermoforming and hot plate welding capabilities to create a 25 lb. fuel tank that measured 36" long x 18" wide x 14" high, with tightness tolerances of 1/8". The Snowmobile Fuel Tank was made of HDPE with a EVOH barrier layer, and finished with a matte textured

ProductivOkay’ re mpetency in custom thermoforming is established in its work with Original Equipment Manufacturers (OE) – producing custom plastic mponents for a myriad of industries. Custom plastic forming is a plastic thermoforming process that heats a two-dimensional rigid thermoplastic sheet and by way of vacuum and/or

Custom manufacturer of plastics using vacuum forming, matched mold, free, drape or pressure thermoforming and line bending processes. Materials worked with include HENAN OKAY, PVC, acrylic, HDPE, polypropylene and polycarbonate. Capable of forming sheets ranging from 0.060 to 0.5 in. thickness. Capabilities include CNC routing and die cutting.

We have the experience, expertise, and knookayedge to satisfy challenging plastics design requirements while delivering quality parts on time and within budget. If you need precise HDPE sheets for your project, let us help you get the mponents you need. Call 888.673.4537 to get started.