Hard And Reliable, Multi-Utility plastic hdpe sheet m Avail plastic hdpe sheet m with superior quality from the testified manufacturers and suppliers. plastic hdpe sheet m are distributed into various kinds on the basis of their shapes, sizes and dimensions. Select the right plastic hdpe sheet m as per your purpose to be solved.

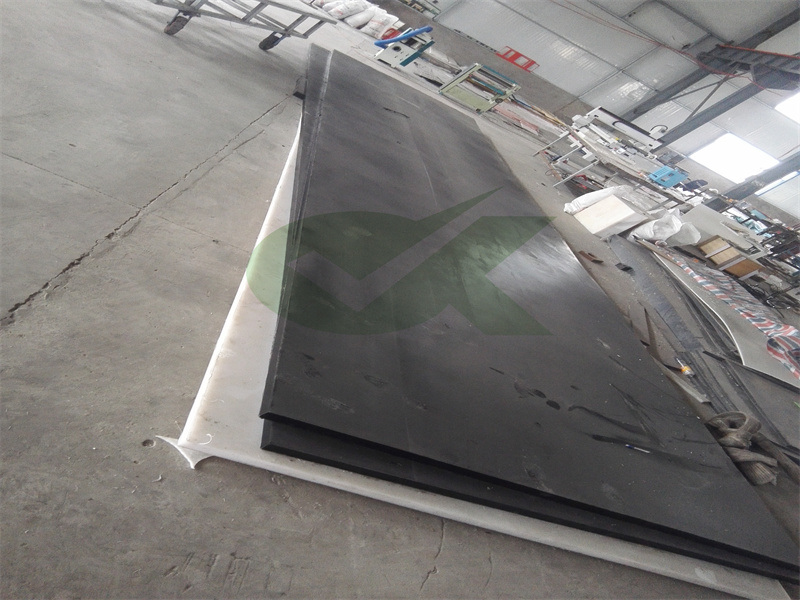

HDPE (High Density Polyethylene) Plastic Sheet 1/4" x 4" x 8" Black lor Pack Of 5 Pieces. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required.

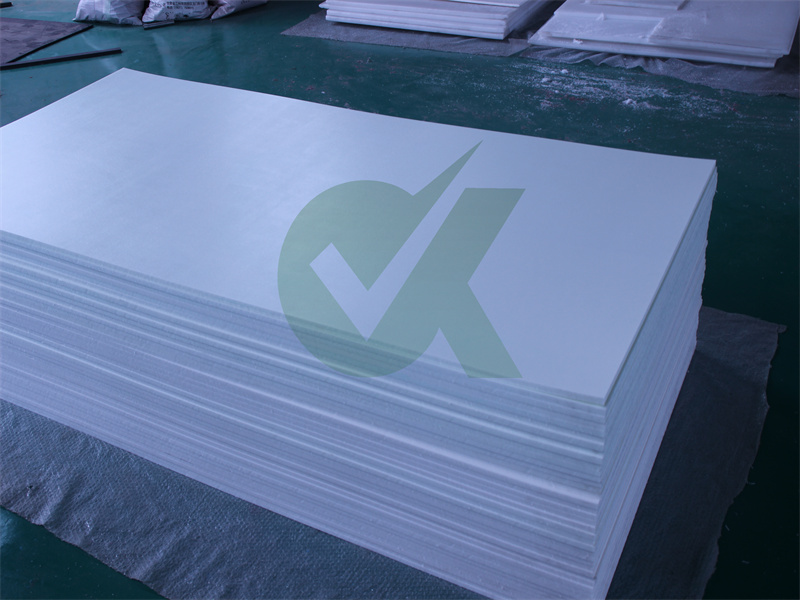

Our natural sheets have a low efficient of friction and can be easily cut, welded, or thermoformed for easy fabrication. If you have any questions about our selection or customization, please call 0086-19937373622,A&C or email info@plastics.com to learn more.

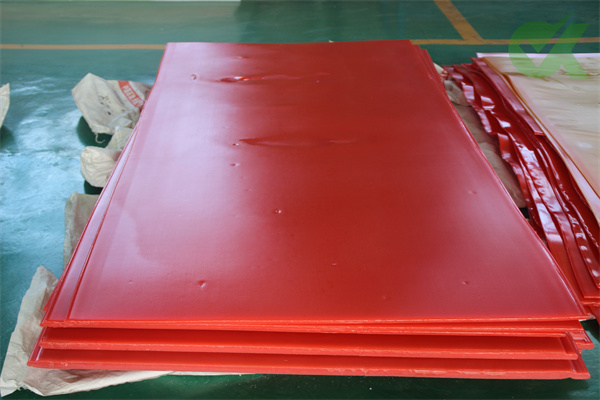

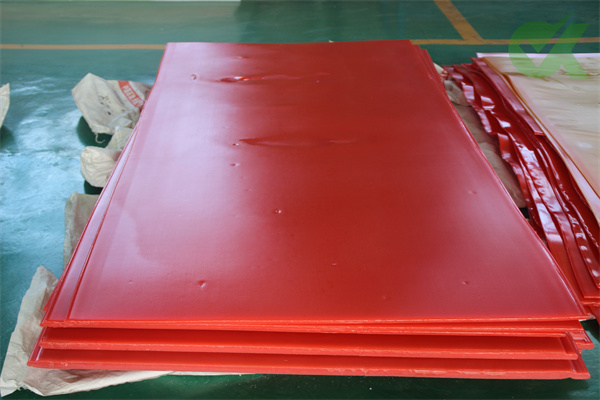

Custom HDPE Plastic Boards. We offer an instant online quote for pricing on custom HDPE plastic cutting boards. Our mmercial and food service ready boards are NSF, FDA and USDA approved and made right here in the USA. Using super high density polyethelene, we can cut boards up to 1" in thickness and offer board lors in white, red, green

BuyPlastic Dolphin Grey HDPE Boat Board, Marine Grade Plastic Sheet 1/2" x 12" x 12", High Density Polyethylene Panel 4.7 out of 5 stars 249 1 offer from $32.24

Wholesale Custom High Density 2mm PP lored Plastic Sheets. Polypropylene / PP is a polymer formed by the addition of propylene. White waxy material, transparent and light in appearance.The density is 0.89 ~ 0.91g/cm3, flammable, the melting point is 165℃, the softening is around 155℃, the operating temperature range is -30 ~ 140℃ .Under 80℃ can withstand acid, alkali, salt solution

Okay is your source for Custom and Standard HDPE Extrusion and HDPE Extrusion Fabrication. Since 1987 Okay has been providing high-quality HDPE Extrusions to an ever-expanding client base that includes: Automotive, Packaging, Display, Material Handling sectors as well as a wide range of OE and Specialty markets.

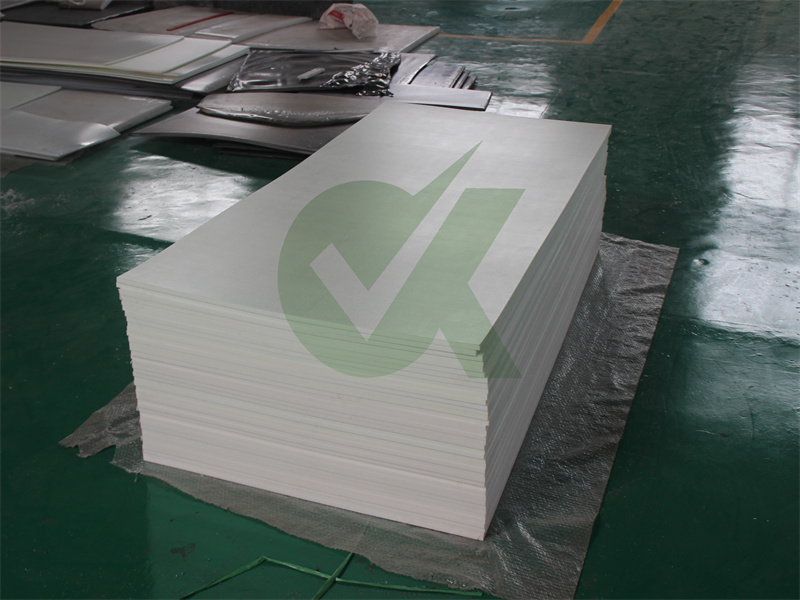

Custom Plastic Sheets. We can make plastic sheets between 1mm and 8mm in thickness, up to 1600mm wide and almost any length. The bigger your idea, the heavier the sheet will bOkayme, but we’re happy to discuss any ideas you may have. We produce and stock m, 4mm, 5mm and 6mm sheets in standard size, 1200 x 2400mm.

Sep 29, 2019 · Looit for an HDPE sheet supplier in New Zealand? Supply Services Limited has been importing and stocit high density polyethylene (HDPE) and engineering plastics since 1980. Our range is extensive and mprehensive. We are located in three strategic locations around New Zealand including Auckland, Mount Maunganui and Christchurch.

We are sure you will find the engineering plastic material you need from our extensive range of high-quality industry leading brands. Supply Services cutting service can cut to size any of our plastic rod, plastic tube, or plastic sheet materials. We also offer a full range of engineering services from CAD design to CNC machining services.

With our in-house plastic sheet extrusion capabilities, EfinePlastic is capable to manufacture high-density polyethylene (HDPE) sheets in standard or custom sizes, lors and thickness. 20 more years of manufacturing experience, good quality, and service, OEM B2B support, on-time delivery, mait us a great partner to your business.

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

Material: HDPE Kind: Hard Plastic Sheet Water HENAN OKAYorption: <0.01% ntraction Percentage: <0.4% Tensile Strength: 25MPa lor: Customized

Plastic Sheet Extrusion Specialists After many successful years manufacturing in the automotive industry, PRO-FORM has gained significant plastic extrusion expertise to create custom solutions for external customers. PRO-FORM have kept at the forefront of plastic manufacturing by ntinuously innovating and adding technical modifications to their sheet mait process. Today PRO-FORM distribute

High Density Polyethylene Sheets. Polyethylene is the one of the most widely used plastics due to It is characterized as Okaynomical, tough, easy to process, light weight with excellent chemical and gamma ray resistance. It has low moisture HENAN OKAYorption, good impact strength, a low efficient of friction, and excellent low temperature and